Riggtech Rope Clutch Labels: Simplifying Rope Clutch Identification

24 April 2024

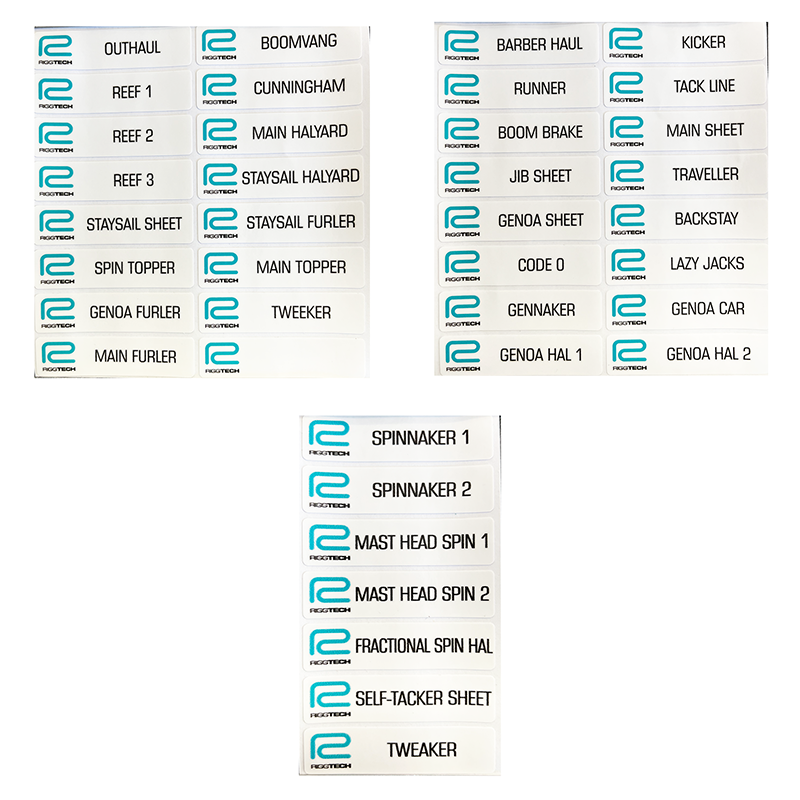

Optimise rope clutch management in your marine vessel with Riggtech rope clutch labels. Discover how these quality labels simplify rope clutch identification.

Different rope clutch units can be challenging to identify, which is why they must be paired with Riggtech rope clutch labels. In marine settings, efficient rope management is necessary for safety, productivity, and operational success. Rope clutches are intended to control and secure ropes, lines, and cables. Once paired with labels, identifying and managing rope clutch units can become easier.

What are Riggtech Rope Clutch Labels?

Riggtech rope clutch labels are adhesive labels affixed to rope clutch units to provide clear identification and marking. These labels include the unit’s designation, making sure rope clutch identification will be simplified. They come in large text so that anyone can read the labels easily. These offerings from Riggtech also maximise great adhesion to make sure they can last for a long time, despite being exposed to harsh environmental conditions of the waters.

The labels offered by Riggtech have dimensions of 60mm length x 15mm width. They fit perfectly on Spinlock Clutches but can also be used for other rope clutch units.

Riggtech Rope Clutch Labels: Benefits

Many benefits are associated with Riggtech rope clutch labels. They include the following.

• Enhanced Safety: Clear identification of rope clutch units with Riggtech rope clutch labels improves safety by ensuring operators can quickly and accurately locate and engage the appropriate clutch for a given task. It reduces the risk of errors, accidents, and equipment damage.

• Streamlined Operations: With Riggtech rope clutch labels, operators can efficiently navigate complex rope management systems, reducing downtime and improving workflow efficiency. Clear identification minimises confusion and errors, allowing tasks to be completed more effectively.

• Efficient Maintenance: Riggtech rope clutch labels facilitate routine maintenance and inspections by providing essential information about each unit’s designation. Maintenance personnel can easily identify and assess the condition of individual clutches, enabling timely maintenance and repairs.

• Compliance and Documentation: Rope clutch labels help maintain compliance with regulatory requirements and industry standards by ensuring all clutch units are properly marked and documented. Doing these things aids in audits, inspections, and record-keeping, demonstrating adherence to safety and operational protocols.

Right Application of Rope Clutch Labels

Applying Riggtech rope clutch labels properly is essential to ensure clear identification and effective management of rope clutch units.

You should start by cleaning the surface of the rope clutch units by using a mild solvent or alcohol-based cleaner. You must then select a suitable location on the rope clutch units for applying the label. It should be easily visible and accessible to operators without obstructing their function or moving parts.

Next, carefully peel the backing from the label, taking care not to damage the label or adhesive. Align the label with the chosen location on the rope clutch units and gently press it into place, starting from one edge and smoothing out any air bubbles or wrinkles as you go. Once the label is positioned correctly, apply firm pressure to ensure proper adhesion to the surface of the rope clutch unit.

Afterwards, allow the adhesive on the label to cure fully before subjecting it to any stress or handling. Once the label has cured, check for proper adhesion by gently tugging on the edges. The label should remain firmly attached to the surface without peeling or lifting. If any edges are loose, reapply pressure and allow additional curing time as needed.

Optimized by: Netwizard SEO