Description

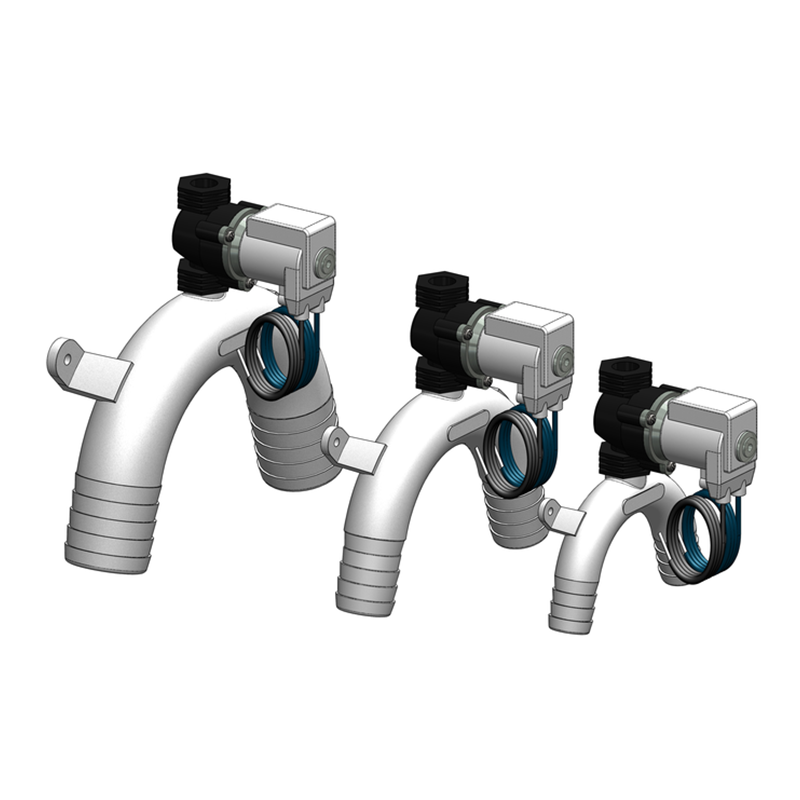

TruDesign Vented Loops with Solenoid are designed and made in New Zealand, Tru-Design Vented Loops with Solenoid are the superior composite siphon break solutions for marine applications. Vented Loops prevent water siphoning from underwater skin fittings back into a vessel and thereby guard against accidental flooding and sinking.

These vented Loops are used predominantly in toilet to overboard applications, toilet inlet applications and holding tank to overboard applications.

A Solenoid controlled Vented Loop allows the vent to be switched to fully closed. This eliminates air entering the system as occurs with a standard vented loop. The solenoid used is normally open, requiring power only to close the valve.

Vented Loops are moulded from a glass reinforced nylon composite. High strength, high-modulus glass fibres impregnated into the nylon provides dramatic strength, stiffness, toughness, and dimensional stability to our loops.

- Manufactured from a glass reinforced nylon composite – High strength and light weight.

- Robust polymer covered solenoid – long life in the marine environment,

- Diaphragm valve – Faster breaking of siphon due to larger flow rate available,

- Female threaded Solenoid Valve – No brass/bronze adapter to corrode.

- Constant internal diameter – No reduction in flow,

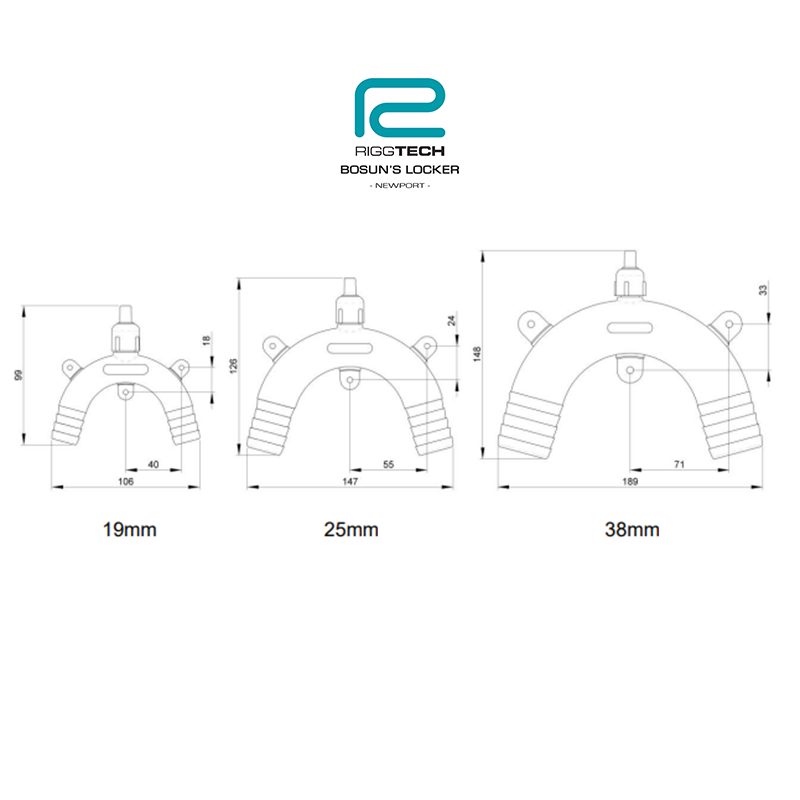

- Self-contained mounting – 3 screw mounting posts give secure and easy installation,

- Chemical resistant – Impervious to diesel, petrol and antifouling paints,

- UV resistant – These fittings will not break down with ultraviolet light or discolour from the sun.

- High quality surface finish – Will not discolour with green film as similar bronze fittings do.

- Large operating temperature range – Suitable for all marine environments, from -40°C to +110°C.